Vention Launches Next-Generation Modular Palletizer to Power its End-of-Line Automation Solutions

July 14, 2025 Vention, creator of what they say is the world’s only full-stack automation platform and hardware ecosystem, announced the launch of its next-generation Rapid Series Palletizer on July 14: the industry’s most versatile palletizing solution engineered for unmatched deployment speed. Available for purchase as of July 14, the updated Rapid Series Palletizer will…

Daily News

Guillevin Presents Smart Square D™ Control Relays

Discover how Square D™ control relays by Schneider Electric turn QO panels into connected solutions, without added complexity. Easy to integrate, they offer precise circuit control, improved energy management, and future-ready flexibility for EV charging or solar power.

Available at Guillevin, with the technical support you need for your projects.

Latest Articles

Featured Article

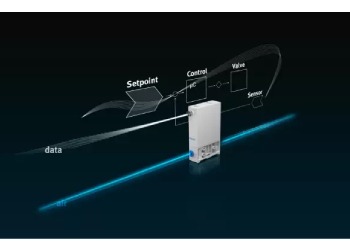

Why it is Important to Optimally Regulate Pressure and Flow

With Controlled Pneumatics, Festo offers the perfect solution by combining proportional technology, sensor systems, and digital control. Read more

Product News

Featured Product

Rigorous Multi-Vendor Ethernet-APL Testing Confirms Readiness for Broad Adoption

A new round of testing by Endress+Hauser of a multi-vendor Ethernet-APL setup has wrapped up successfully, further validating the technology’s readiness for widespread deployment. Ethernet-APL is becoming a must-have tool for advancing the digitalization of process plant operations for optimized performance and other major benefits. Read more